Service Information

The coffee processing is concerned through ensuring production of good quality products that competes in the international market. Such services include:

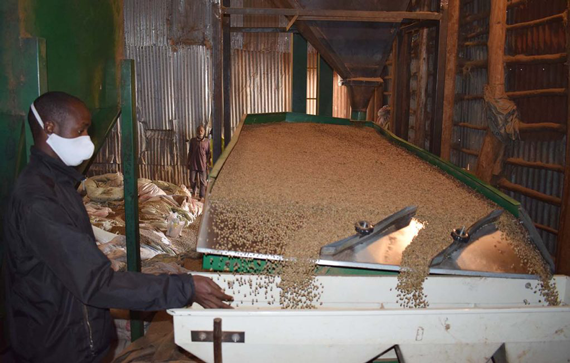

Receiving Dry Rob Coffee cherry

The Company receives dry Robusta coffee cherry from large scale farmers, small-scale farmers and cherry coffee buyers within the region. Seasonally the company can receive up to 20,000 tons of dry coffee cherry from farmers and coffee buyers.

Customer coffee being received, ready to be processed

Milling of coffee

From the cherry coffee warehouse, the coffee cherry processed in the three factories is by the following steps.

Pre-cleaners

Each factory has its own pre-cleaners that is a De-stoner machine to remove all stones in the coffee beans and a Regulator machine to remove other forms of dirt like ropes, leaves, stones, small branches of coffee trees and all other forms of dirt during the processing of the coffee.

De-Stoner Machine used by KMC workers to remove stones

Hulling of coffee

The company has three factories with which each factory has two hullers and catordoor which mill the dry coffee as the result dry clean coffee has all different grades. Drying clean Coffee The company has a coffee drying machine (Dryer) with the capacity of drying 20 tons of coffee per hour depending on the moisture content of the milled coffee so as to reach up to the demands of the buyer’s moisture content.

Gravity Color Sorting Machine which is used to grade Coffee

Grade Clean Coffee as per TCB (Tanzania Coffee Board) standards.

Each factory has its own grading machines each having the capacity to grade 5 tons of clean coffee per hour ready to grade the clean coffee beans into different grades as per Tanzania Coffee Board Standards that is screen no 18 which is Extra, Screen No. 16 which is superior, Screen No.14 which is FAQ Standard and Screen No.12 which is (UG). Other standards are Triage (TR) and BHP blacks also processed as per buyer’s choice.

Gravity and Color sorting of clean coffee to remove Blacks & husks.

The company has two color sorters each with a gravity machine. Each color sorter has the capacity of sorting 6 tons that is to make a total of 12 tons of clean graded coffee per hour. The machinery are to remove husks ,discolored coffee and beans during processing to ensure proper quality of clean coffee produced with qualities to compete in the world trade market and also to reach up to the buyer’s satisfaction.

COFFEE PRODUCED AND SOLD TO EXPORTERS

|

|

CHERRY COFFEE PRODUCED (MTs)

|

CLEAN COFEEE PROCECED (MTs)

|

|

|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Contact Us NOW

COFFEE PROCESSING | Tanzania

Karagwe Marketing Co. Ltd

The coffee processing is concerned through ensuring production of good quality products that competes in the international market.

View Details

COFFEE FARMING | Tanzania

Karagwe Marketing Co. Ltd

The company has been working in hand to make sure that the main streams for coffee collection doesn’t disappear through coffee farming services

View Details

COFFEE BRANDING & MARKETING | Tanzania

Karagwe Marketing Co. Ltd

Our branding and marketing strategies are as follows: Coffee received is acceptable and of good quality at our factories Proper outturn ratios are being maintained

View Details

<

COFFEE PROCESSING

Karagwe Marketing Co. Ltd

COFFEE FARMING

Karagwe Marketing Co. Ltd

COFFEE BRANDING & MARKETING

Karagwe Marketing Co. Ltd